Products & Services

Our electronic-grade wastewater treatment technology efficiently and economically adapts to the specific characteristics of impurities through targeted processes. By integrating multi-stage chemical coagulation and sedimentation, ammonia nitrogen stripping, and biological treatment, chip manufacturing wastewater containing a wide range of pollutants with complex properties can be effectively treated, achieving deep pollutant removal. We are capable of handling over 15 types of chip wastewater, covering all potential wastewater types produced by advanced process lines, offering high treatment efficiency with low operating costs.

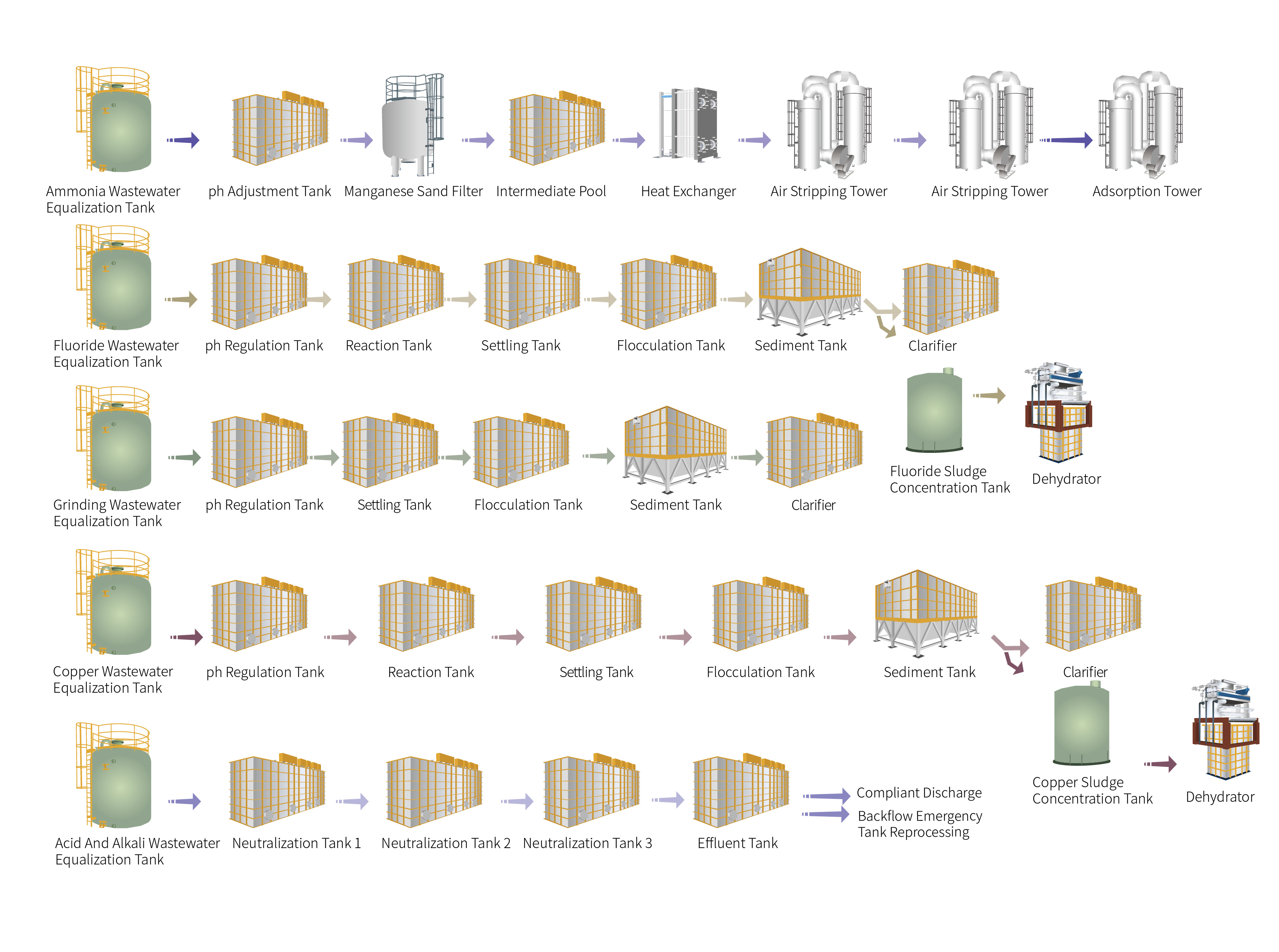

The production process of chips is kind of demanding, including cleaning silicon wafers, chemical vapor deposition, and etching, which are repeatedly carried out. During the process, a large number of chemical reagents and special gases are consumed, and manifold heavy metal ions come out, after being cleaned with UPW, turn into chip wastewater of complex composition. Compared to traditional industrial wastewater and urban sewage, chip wastewater contains more types of pollutants and components, making it more difficult to treat. With the rapid development of advanced chip processes, the concentration of pollutants such as chromium and nickel in chip wastewater is increasing, and special treatment is needed thus, promoting the continuous progress of wastewater treatment technology. Up to now, Gaopin Tech can deal with more than 15 types of chip wastewater, covering all types of wastewater that may be generated by advanced process production lines. The main technologies involved in typical wastewater treatment are as follows:

|

Treatment process |

Technical key points |

|

pH control |

Control the dosing time and dosage based on the fluctuation of pH values to achieve precise dosing and improve the stability of wastewater pH. |

|

Multi-stage chemical coagulation and precipitation |

Make the particles in water fully react with reactants to precipitate and remove impurities that come with chip production and exist in wastewater, such as fluorine, copper, chromium, and nickel, and after the process, to maintain the total suspended solids (TSS) in the chip wastewater less than 20 ppm. In order to achieve the best effect of chemical coagulation and precipitation, reasonably adjust and control the type and dosage of chemicals, wastewater flow rate, stirrig method, precipitation pond shape, and other aspects. |

|

Ammonia-nitrogen blowoff |

Based on the theories of gas-liquid equilibrium and mass transfer velocity, air blow wastewater under alkaline conditions to maintain the concentration of ammonia in the gas always lower than the equilibrium concentration, which makes the dissolved ammonia in the wastewater continuously pass through the gas-liquid interface and ultimately removes NH3-N from the wastewater. In order to improve the removal rate and achieve effective removal of ammonia and nitrogen in wastewater, strictly control parameters such as wastewater pH and temperature, gas-liquid ratio, and blowoff duration. |

|

Biological treatment |

Convert toxic substances into non-toxic substances through biochemical reactions within microorganisms, effectively decomposing toxic substances in chip wastewater. The difficulty of biological treatment technology lies in maintaining the cellular activity, reproduction, and metabolic efficiency of active bacterial communities, so it is necessary to control parameters such as pond shape, sludge concentration, microbial concentration, and oxygen content. |

|

Logic chips |

Memory chips |

Power chips |

Packaging testing |

Next-gen semiconductors |

|

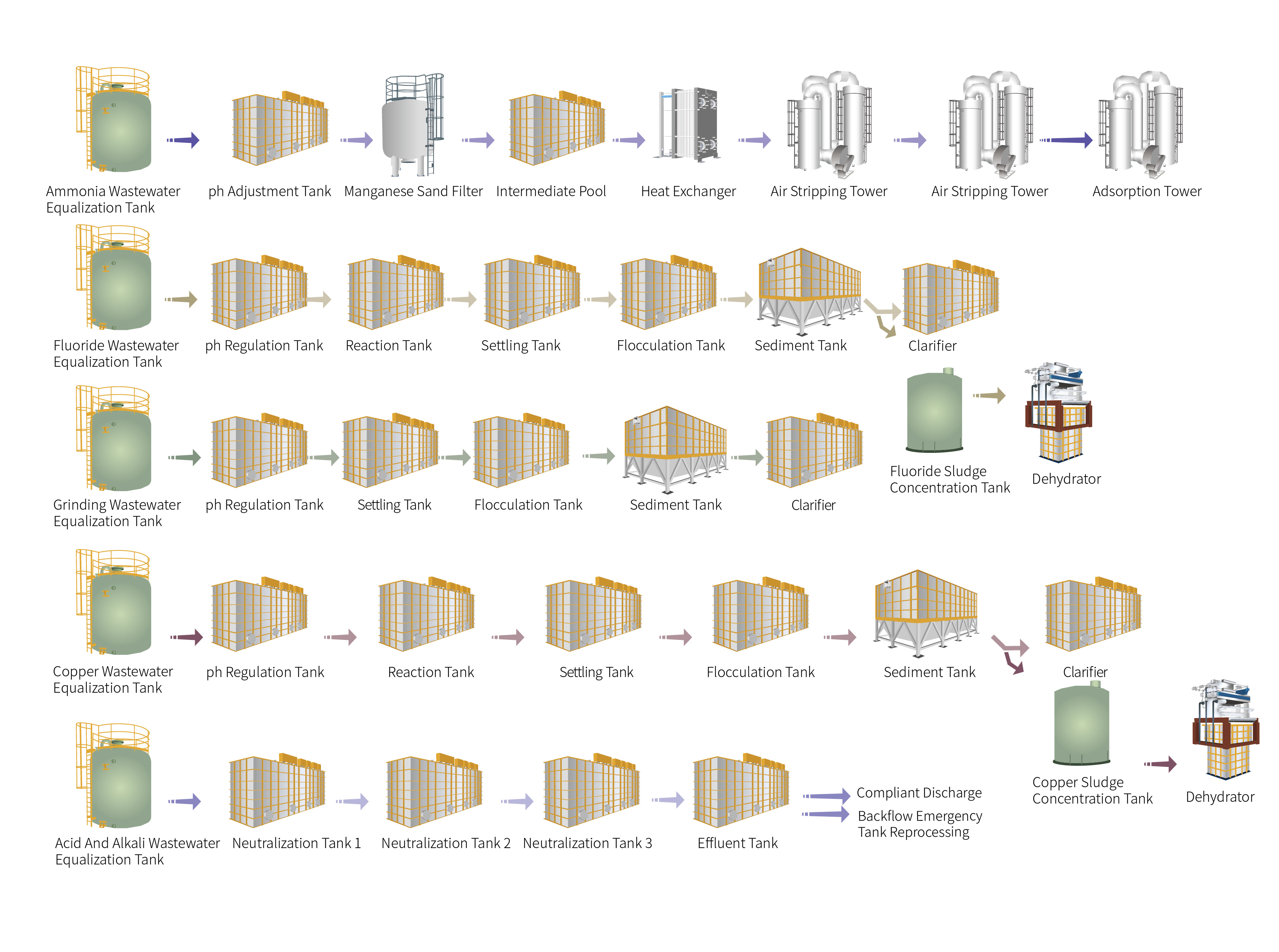

Fluoric-containing wastewater system |

Fluoric-containing wastewater system |

Fluoric-containing wastewater system |

cutting wastewater system |

Fluoric-containing wastewater system |

|

Grinding wastewater system |

Grinding wastewater system |

Grinding wastewater system |

Back Grinding (BG) wastewater system |

Grinding wastewater system |

|

Copper-containing wastewater system |

Copper-containing wastewater system |

Copper-containing wastewater system |

Nickel-zinc wastewater system |

Ammonia nitrogen wastewater system |

|

Ammonia nitrogen wastewater system |

Ammonia nitrogen wastewater system |

Ammonia nitrogen wastewater system |

Copper-containing wastewater system |

Organic wastewater system |

|

Acid and alkali wastewater system |

Acid and alkali wastewater system |

Acid and alkali wastewater system |

Tin-containing wastewater system |

Acid and alkali wastewater system |

|

Organic wastewater system |

Organic wastewater system |

Nickel-containing wastewater system |

||

|

HF/IPA wastewater system |

Arsenic-containing wastewater system |

Chromium-containing wastewater system |

||

|

TMAH wastewater system |

Gold-containing wastewater system |

|||

|

BOE wastewater system |

Palladium-containing wastewater system |

|||

|

Recycled water system |

Cyanide-containing wastewater system |

|||

|

Organic wastewater system |

||||

|

Recycled water system |

Previous Page:

Next page: