GOALPURE is an independent sub-brand established by High-Frequency Technology, specializing in the R&D, promotion, and application of key process products and chemical agents for ultrapure water and closed-loop recycling solutions. Market promotion and industry applications are primarily conducted through Aike International Trade (Hainan) Co., Ltd., a wholly-owned subsidiary of High-Frequency Technology.

Leveraging our extensive process expertise and technological capabilities in the field of ultrapure water for high-end semiconductor manufacturing, we have joined forces with international roll-membrane separation manufacturers, leading domestic reverse osmosis membrane companies, the vice-chairman unit of China’s ion-exchange resin industry, top domestic enterprises specializing in adsorption and separation materials, and a comprehensive Chinese company offering premium UV technologies, products, and services. Together, we are focusing on three key technologies in semiconductor ultrapure water processes: reverse osmosis, ion exchange, and UV-based TOC degradation and sterilization. We are jointly developing and specifically producing the GOALPURE series of reverse osmosis membrane elements, resin product lines, and UV-based water treatment equipment—products that precisely and continuously meet the demands of advanced processes and technological advancements in semiconductor ultrapure water systems.

GOALPURE RO Membrane

Leveraging our more than two decades of expertise and technological capabilities in ultra-pure water processing within the high-end semiconductor manufacturing industry—particularly in areas such as chips and displays—we have teamed up with renowned manufacturers of spiral-wound membrane separation systems and reverse osmosis membrane companies. Relying on their "National-Local Joint Engineering Research Center for Separation Membrane Materials and Application Technologies," we have focused on reverse osmosis technology for ultra-pure water in the semiconductor industry, jointly developing and producing the GOALPURE series of reverse osmosis membrane elements that feature precision, stability, high flux, and low energy consumption.

Technical Features and Advantages

Stability

In real-world applications of ultrapure water systems for semiconductors, the membrane sheets used in the GOALPURE series reverse osmosis membrane elements undergo an improved interfacial polymerization process during manufacturing. This process enhances the diffusion rate of monomers, strengthening the desalination layer structure. As a result, the thickness of the desalination layer has been increased from the conventional ~150 nm to ~300 nm, significantly improving product stability.

Wash-resistant

To meet the stringent requirements of semiconductor ultrapure water systems, the GOALPURE series reverse osmosis membrane elements have undergone improved and optimized functional layer process design, significantly enhancing both the stability of product water quality and the chemical resistance of the membrane sheets.

High-throughput

Meeting the stringent water quality requirements of semiconductor ultrapure water systems, the GOALPURE series reverse osmosis membrane elements have demonstrated membrane flux performance that is consistent with the benchmark of imported counterpart products, as verified through extensive testing across multiple scenarios.

High desalination rate

Meeting the stringent water quality requirements of semiconductor ultrapure water systems, the GOALPURE series reverse osmosis membrane elements have demonstrated a desalination rate that is on par with benchmark imported products, as verified through extensive testing across multiple application scenarios.

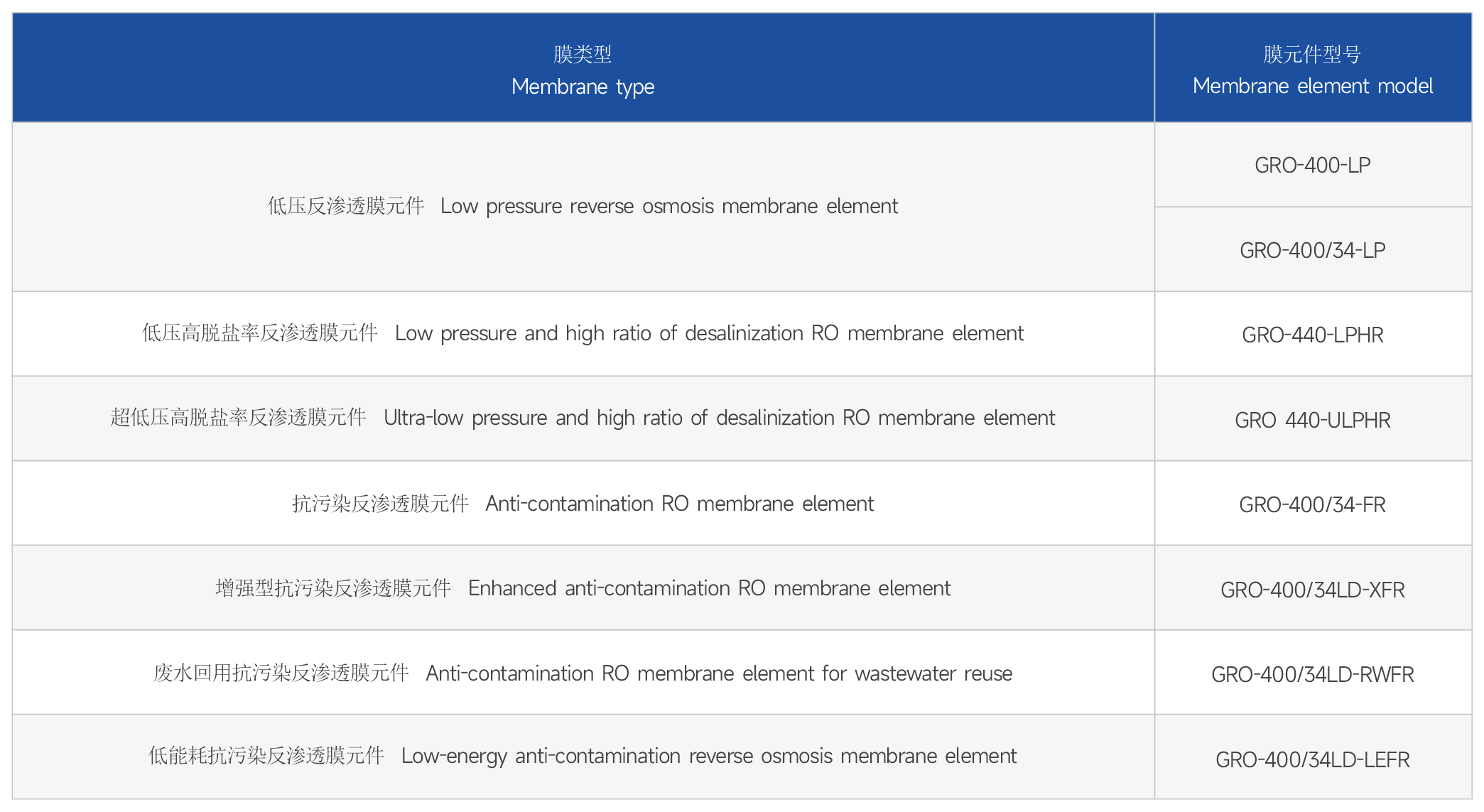

Product Model

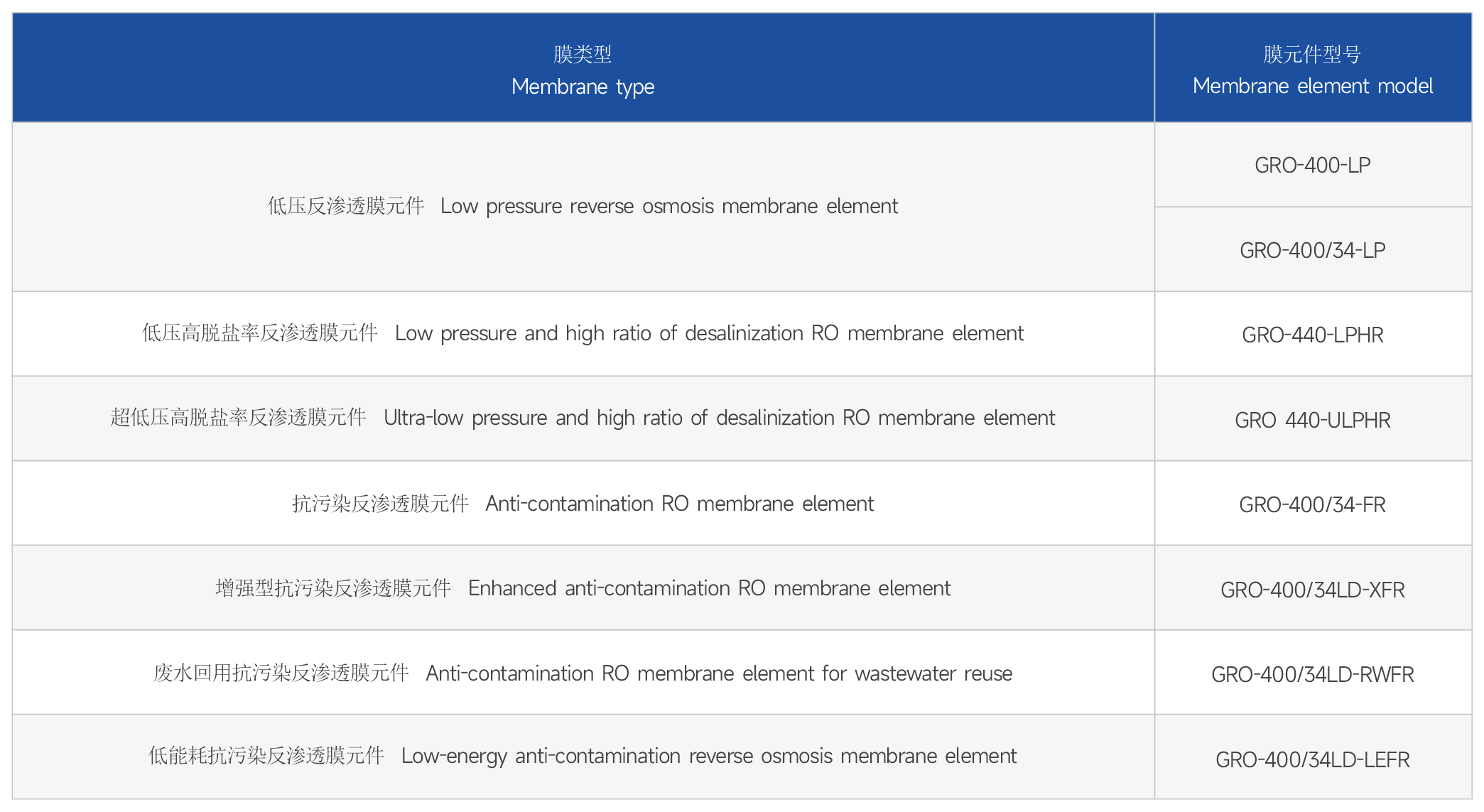

| Membrane type |

Membrane element model |

| Low-pressure reverse osmosis membrane element |

GRO-400/34LD-LP |

| GRO-400/34-LP |

| Ultra-low-pressure, high-desalination-recovery reverse osmosis membrane element |

GRO-440/28-LPHR |

| Ultra-low-pressure reverse osmosis membrane element |

GRO-440/34-ULPUP |

| Ultra-low-pressure, high-desalination-recovery reverse osmosis membrane element |

GRO-400/28-ULPHR |

| Anti-pollution reverse osmosis membrane element |

GRO-400/34-FR |

| Wastewater Reuse Anti-Fouling Reverse Osmosis Membrane Elements |

GRO-400/34-RWFR |

| Low-energy, anti-fouling reverse osmosis membrane element |

GRO-400/34LD-LEFR |

Leveraging our more than 20 years of expertise and technological capabilities in ultrapure water treatment—acquired through our leadership in the high-end semiconductor manufacturing sectors such as chips and displays—we have joined forces with Wharton Technology, a globally renowned manufacturer of spiral-wound membrane separation systems and a leading domestic player in reverse osmosis membranes. Relying on Wharton Technology’s “National-Local Joint Engineering Research Center for Separation Membrane Materials and Application Technologies,” we are focusing on advanced reverse osmosis technology for ultrapure water in the semiconductor industry. Together, we have jointly developed and manufactured the GOALPURE series of reverse osmosis membrane elements, which feature greater precision, enhanced stability, higher flux, and lower energy consumption.

GOALPURE is an independent sub-brand established by High-Frequency Technology, specializing in the R&D, promotion, and application of key process products and chemical agents for ultrapure water and closed-loop recycling solutions. Market promotion and industry applications are primarily conducted through Aike International Trade (Hainan) Co., Ltd., a wholly-owned subsidiary of High-Frequency Technology.

Leveraging our extensive process expertise and technological capabilities in the field of ultrapure water for high-end semiconductor manufacturing, we have joined forces with globally renowned spiral-wound membrane separation manufacturers, China’s leading reverse osmosis membrane enterprise, a vice-chairman unit of China’s ion-exchange resin industry, a domestic leader in adsorption and separation materials, and a top-tier domestic UV technology provider. Together, we are committed to focusing on three key technologies in semiconductor ultrapure water processes—reverse osmosis, ion exchange, and UV-based TOC degradation and sterilization—and are jointly developing and specially producing the GOALPURE series of reverse osmosis membrane elements, resin products, and UV-based water treatment equipment. This collaboration enables us to more precisely and continuously meet the demands of advanced processes and technological advancements in semiconductor ultrapure water systems.

Technical Features and Advantages

More stable

In real-world applications of ultrapure water systems for semiconductors, the membrane sheets in the GOALPURE series reverse osmosis membrane elements undergo an improved interfacial polymerization process during manufacturing. This process enhances the diffusion rate of monomers, strengthening the desalination layer structure. As a result, the thickness of the desalination layer has been increased from the conventional ~150 nm to ~300 nm. While significantly improving product stability, this enhancement also boosts the membrane sheets' resistance to chemical cleaning.

More precise

To meet the high-end requirements of semiconductor ultrapure water systems, the GOALPURE series reverse osmosis membrane elements have been optimized in terms of raw materials and manufacturing processes. They exhibit superior removal rates for impurity ions such as CI⁻, NO₃⁻, HCO₃⁻, and B, as well as for TOC, compared to leading products on the market.

Higher throughput

Compared to premium imported products and previous-generation products, the GOALPURE series reverse osmosis membrane elements consistently deliver equal or even higher flux rates under a variety of feedwater conditions characterized by different concentrations of sodium chloride, magnesium chloride, calcium nitrate, and sodium nitrate, as well as varying pH levels.

Better performance

In addition, it exhibits higher removal rates for organic compounds such as isopropanol, glycine, and glucose, and demonstrates consistent—or even superior—performance under various pH conditions. Moreover, it outperforms other materials under acidic, low-pressure, high-temperature, and high-salinity conditions.

Product Model

GOALPURE Reverse Osmosis Membrane Element Classification